Direct-to-garment or Dtg printing is a process of printing on clothing using modified inkjet technology, just like a home printer but fancier. DTG printers applies specialized textile inks directly into the fibers of the clothing that is being printed.

dtg advantages

Over the last ten years, the resolution of direct to garment printers has increased dramatically. This means that DTG prints can look better than traditional apparel printing processes, such as screen printing. You can’t feel the design on the garment, like in screen printing, since the design is printed into the fabric of the apparel.

At the same time, the cost to set up direct to garment printers has decreased – which means DTG printing has become more accessible and affordable than many traditional printing methods.

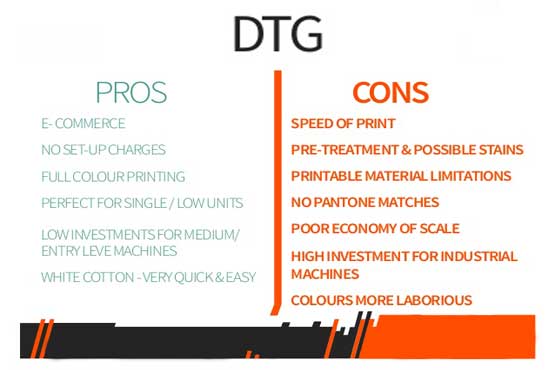

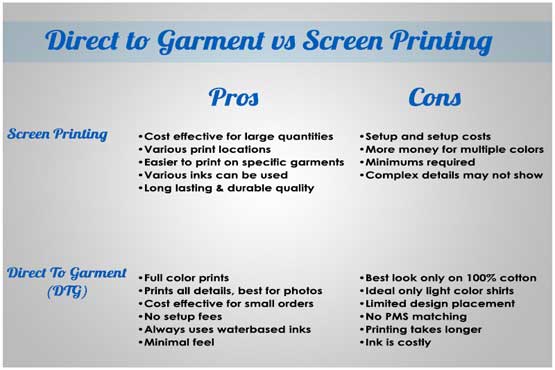

Direct to garment printing offers great advantages over traditional printing, such as live previews of prints, and running multiple printers from one PC. The amount of time & labor involved with DTG is significantly lower than traditional methods. It’s easy to print full color, intricately detailed prints either in volume or one at a time. This makes low volume orders easy to fulfill and frees up time to print more orders and keep DTG pricing quite competitive.

dtg limitations

Even with all the cost and time benefits, there are a few setbacks with DTG printing. In order for a printed design to look correct on dark materials, a white underlayer must be printed before the color is applied. Many DTG printers do not print white ink on white/ light color garments before applying colored inks, which means your design may not look as good on dark garments than light garments.

An issue that may happen is that the shirt moves a little and so you can see a thin white line around the design which is the white underlayer. DTG inks are also a little more expensive than traditional printing inks. Direct to Garment printing takes less time to set up than traditional screen printing; however, the printing process itself takes longer per item. Unlike screen printing, where the setup takes the longest and the printing itself is relatively quick, there are no real price or time discounts when using DTG printing in volume.

is dtg printing eco-friendly?

Yes, DTG printing typically uses water-based, pigmented inks. Manufacturers often source these inks naturally, making them environmentally friendly. Here at L.A. Dtg Printing we use Brother Genuine inks.

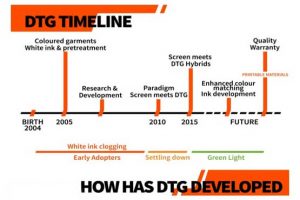

History of Dtg printing

DTG printing is a relatively new technology (within the last 20 or so years). It was introduced around 1996 at a trade show in Tampa, Florida. In 1998, Brother, Intl. began to develop proprietary DTG printers, beta testing them until 2003, with a first showing at an Atlantic City, NJ trade show in 2005.

The technology is now commonplace. Decorated apparel companies around the globe use DTG printers to fulfill t-shirt or custom apparel print orders.

how long does dtg printing last?

DTG prints will remain just as bright and soft and won’t crack when properly cared for. Follow our guide to t-shirt care to avoid cracking or fading.

Dtg print VS Screen printing?

how much is a dtg PRINTER?

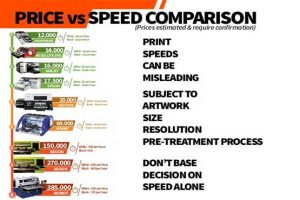

There are several leading brands manufacturing Direct garment printers. Brother, Epson, Anajet, Kornit, and M&R are among the leading brands developing DTG printer technologies. The printer prices range from $11,000 to $200,000, depending on their level of sophistication.